Catching the future of servo technology trend, ISMC micro servo faces high-end industrial applications

Manufacturing automation continues to set off an upsurge, along with industrial upgrading, equipment processing accuracy requirements, servo system into the market growth period. The market scale of China's servo industry has shown an obvious growth trend. In 2021, the market scale of China's servo system reached 12.197 billion yuan, an increase of 8.42% over the previous year, and in 2022, the market scale reached about 18 billion yuan. Demand growth has attracted a large number of "players" to enter the market, at the same time, the trend of intellectualization, high precision and high performance, generalization and miniaturization is becoming more and more obvious, and a new pattern of servo market is taking shape..

In this regard, recently, at the 2023 Munich Shanghai Electronic Production Equipment Exhibition, OFweek Vico interviewed Zhang Longfei, general manager of ISMC, one of the representative enterprises in the field of micro-servo, and put forward analysis and prospects on the development of ISMC and the research and judgment of the servo industry.

01.

International R & D gene, 5 years to cultivate a product

Experienced from hydraulic, pneumatic to electrical process, servo system is becoming more and more mature, the market is becoming more and more diversified, as one of the supporting technologies of industrial automation, the competition of servo products is becoming increasingly obvious, and the core of competition lies in technology. For a long time, ISMC has been a low-key existence, concentrating on R & D and building good products. Since 2015, the company's first-line R & D team from the world's top 500 companies has introduced the v-model forward R & D management system. After a lot of market research, starting from the needs of customers and industries, it redefines products, carries out top-level product architecture design, and finally transforms them into hardware, software, machinery, EMC and other designs. After the functional prototype is launched, it must undergo further product specification testing, including reliability testing, environmental testing, safety testing, etc., before the next generation of performance prototype can be launched, product performance verification can be carried out, the degree to which the product meets the design function can be tested, and finally the reliability prototype can be formed. At this time, the product is not enough to enter the market. In order to further meet the needs of users, ISMC products need to be applied for more than half a year, cooperate with product process management, establish quality procurement, supply chain production and testing system before they can be introduced to the market. For the company, this is a complex, rigorous and costly process, but when delivered to users, it brings controllable quality and higher performance. Finally, after five years of dormancy, ISMC was certified by various international standards and began to enter the market and customers. At the Munich Shanghai Electronic Production Equipment Exhibition, ISMC brings the analog quantity and PWM duty cycle function display platform of servo products, Ruby six-in-one product dynamic display platform, Ruby Plus three-in-one product dynamic display platform, ISMC servo Z-axis application product dynamic show platform, ISMC servo multi-motor type display platform and ISMC servo linear motor dynamic show platform. Seven key products of ISMC servo soft landing function dynamic display platform attract a large number of on-site audiences to understand and communicate.

General Manager Zhang Longfei introduced the exhibits to the audience.

02.

Reliability and stability, shaping the uniqueness of ISMC

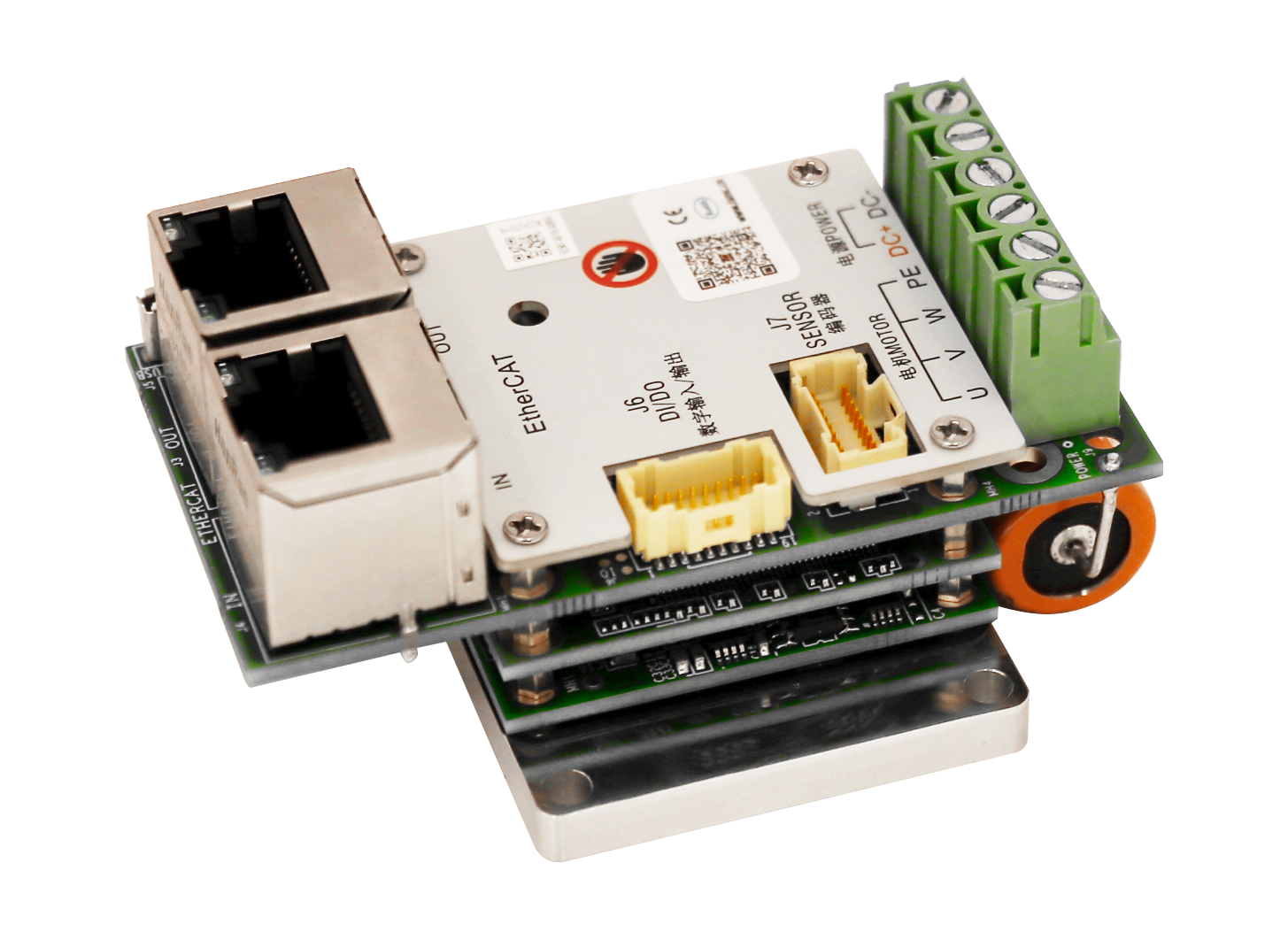

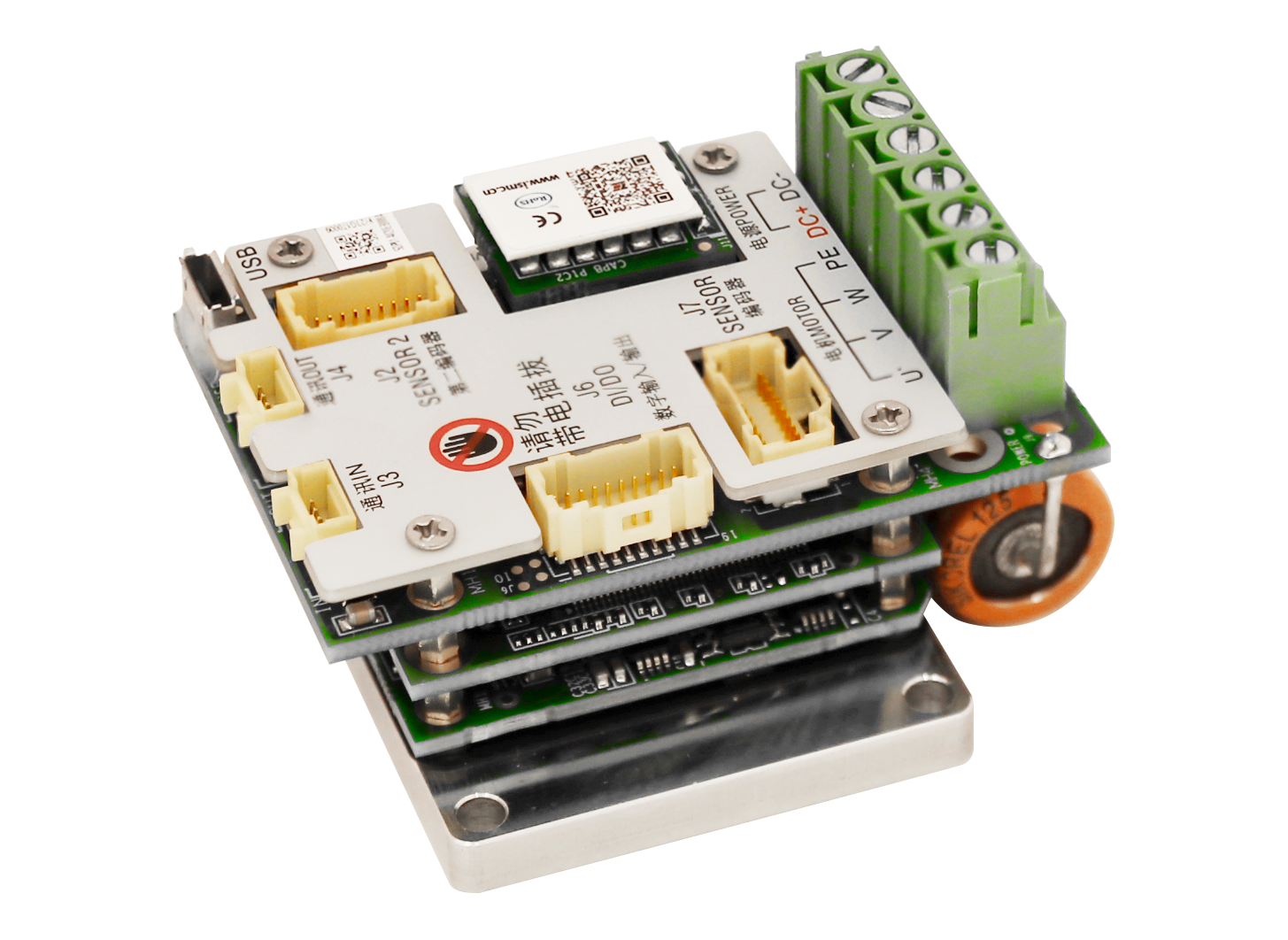

Miniaturization is becoming the common pursuit of manufacturing industry. Lightweight production and cost considerations make all kinds of production equipment manufacturers pursue smaller size, but also more stable and reliable performance. As far as servo is concerned, the requirements are even higher. The servo system requires the servo driver and the servo motor to complement each other in order to improve the performance of the servo system as a whole. Therefore, the design and production of servo products should be considered in an all-round way. More than that, ISMC observes that at this stage, many automation devices are pursuing smaller, more integrated, more functional and stronger performance, and the components they need are more high-end. This trend not only appears in the overall equipment, but also in the miniaturization of components such as drivers, motors, controllers and even power supplies, which requires a very high level of product modularization, just in line with ISMC's product positioning. As a representative enterprise of micro-servo, ISMC's servo products are about one tenth of the volume of ordinary AC servo, which can be closer to motor installation, improve response accuracy and efficiency, and help customers reduce the size of equipment by 30% -50%. At the same time, the connection cable is shorter, which can reduce the interference of the encoder, enhance the reliability of the connection, realize plug and play, and reduce the maintenance cost of customers. On the other hand, ISMC's products can be compatible with almost all motors and encoders. Relying on the professional algorithm created by the software team, a driver can be matched with a variety of motors, thus realizing the modularization of hardware. Customers can match what they need, which can greatly improve supply chain management, equipment usability and reliability. Finally, ISMC's own advantages and competitiveness have been formed, and unique products and brands have been created.

03.

Do a good job of servo for users

Due to the reliability of performance and the consistency of quality, ISMC focuses on the high-end manufacturing industry with precision as its prominent feature, and uses its own strength to empower semiconductors, lithium batteries, photovoltaics, production testing equipment and medical equipment. In less than three years since its introduction to the market, ISMC has entered more than 500 customer applications and established its brand in the manufacturing equipment manufacturing industry.

Taking the semiconductor industry as an example, ISMC can be found in the equipment needed in the whole process, including wafer manufacturing, wafer testing, chip packaging, testing and other links, especially with high-end customers in key industrial chains such as mobile phone manufacturing. In addition, Zhang Longfei revealed that the servo products of ISMC are also used in the lithography machine, which is an important core equipment for manufacturing chips. This is enough to show its strength in precision high-end production. At present, the company has a professional R & D team in Shanghai, which can achieve rapid response to domestic users. Facing the market with diverse needs, ISMC has launched diversified products in line with international standards to achieve reliable delivery in large quantities. At the same time, it provides high-end customized services to leading enterprises in various industries that have reached the international level. From technology to products, from application to promotion, with the support of strong technical strength and professional product capabilities, ISMC has attracted attention after a long silence. Zhang Longfei said that in 2023, ISMC will launch more and more creative differentiated products, and at the same time, with the combination of products.