ISMC released Micro Servo Systems in the World

In recent years, with the development of electronic manufacturing, semiconductor, robotics, and other industries, production lines have increasingly high demands for processing efficiency, processing accuracy, and equipment miniaturization. However, due to the limitations of installation space, traditional AC servo systems can only be installed in the electric control cabinet, and complex drag chain cables have to be used to connect the motor and driver, which makes the equipment extremely bulky, not only bringing long-term reliability issues, This increases system costs and maintenance costs, reduces the response performance of the servo system, and increases EMC interference, especially switching frequency limitations, making it difficult for the bandwidth of traditional AC servo systems to meet the requirements of highly responsive scenarios. In response to this contradiction, the miniaturization and high-frequency of servo systems become inevitable. The new micro servo system uses a new generation of servo technology, with a power density of more than ten times larger than traditional AC servo, a size of only one tenth of that of traditional AC servo, and a bandwidth that can be twice or even more than five times higher than traditional AC servo. Compared to traditional AC servo systems, this micro servo system not only significantly improves performance and saves size, but also brings new changes to the installation location. It can be installed close to the motor, perform power supply and network networking on the motion mechanism, almost eliminating drag chains and electric control cabinets, not only greatly reducing system costs and maintenance costs, which is conducive to the modular design of the system, but also making the equipment smaller and more responsive High accuracy to the extreme.

Traditional servo scheme drag chain cables: 4 * N power cables+5-13 * N encoder cables As the number of shafts increases, the electric control cabinet and drag chain cables become larger and larger, and the system performance and reliability gradually decrease.

Micro servo system is a new generation of servo solution, using a common DC bus architecture, composed of power supply, micro servo controller, servo motor, signal cable, and power cable.

Drag chain cable: Regardless of the number of axles, the electric control cabinet and drag chain cable remain unchanged, and the system performance and reliability are greatly improved.

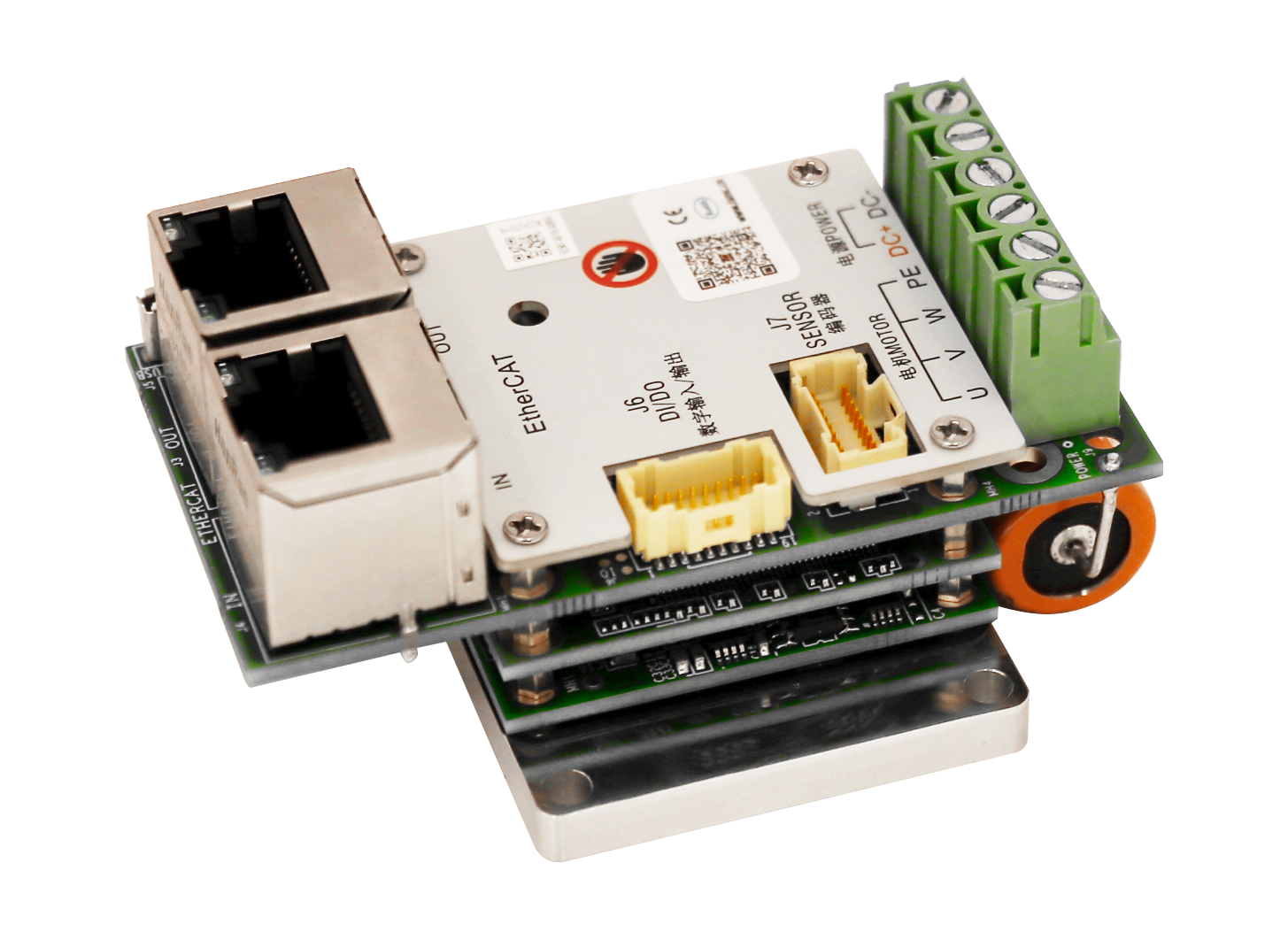

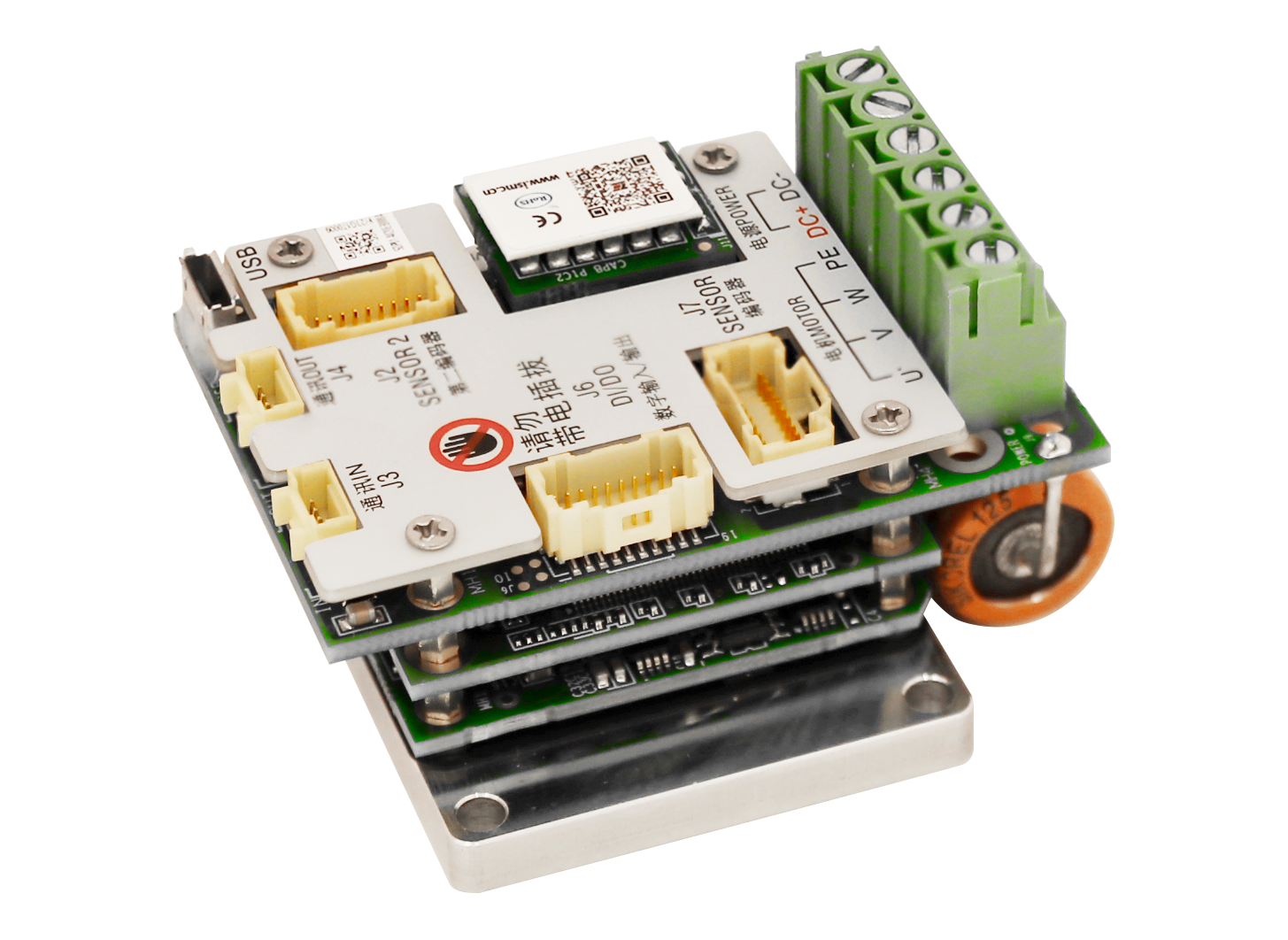

"Bringing servo controllers closer to the motor, significantly reducing cables, saving space, reducing costs, and improving responsiveness, reliability, safety, and ease of use, especially in industries such as electronic manufacturing, semiconductor, and robotics. The new generation of micro servo systems has a dynamic performance improvement of more than 30% compared to traditional servo solutions, higher force control accuracy, and smaller EMC, making them particularly suitable for small and precise equipment, such as chip front and rear processing." "Industrial equipment, etc." The Diamond series servo controller released by ISMC is a new generation of micro servo controller products, integrating all servo functions in a small space, and achieving world-class performance. It is fully developed in accordance with the European R&D management process V model, meeting the European IEC61800 standard, passing CE certification, and possessing European product quality.

Its main product features include:

1) High power density: size only 4 * 4 * 2.5cm, weight only 50g, rated power 0-750w, instantaneous power up to 3000w.

2) Ultra fast response: current loop bandwidth 4500Hz, speed loop bandwidth 1500Hz.

3) Precision force control: up to 0.01 A high-precision current control.

4) Strong master control adaptation: support EtherCAT, CANopen, Modbus communication, analog quantity, and pulse control; Support the CIA402 protocol; It can be adapted to mainstream controllers in the industry such as BEST, OMRON, and ACS.

5) Suitable for various motor types: supporting rotary servo motors, voice coil motors, linear motors, torque motors (DD motors), brushless motors, brushless motors, hollow cup motors, frameless motors, speed reduction motors, etc.

6) Multiple encoder adaptations: Support incremental, absolute, and Hall encoder functions, and will soon cover almost all absolute value protocols in the industry.

7) Ultra high European quality: Meet the V model R&D management process, and pass the international standards of IEC61800 and ISO9001.

8) Low power consumption: efficiency is close to 99%.

9) High usability: Full Chinese debugging interface, convenient configuration, and simple debugging.

10) Enhanced features: support for soft landing; Support full closed-loop; Support resonance filtering; Advanced features such as flying racquet and gantry synchronization will soon be supported.

"Product quality+product innovation=foothold," said Zhang Longfei, head of ISMC China. "Research and development management and production management determine product quality. Our company's products are developed strictly in accordance with European standards, and it took five years of research, development, and testing to enter the market. The high requirements stem from the team's ten years of accumulation in international first-class brands, as well as its responsibility and commitment to the industry.". "We pay more attention to the pain points of our customers and are committed to leading the industry's solution transformation through technological innovation, providing high-end products that meet the Chinese market.".

"The current homogeneous competition in the AC servo industry is severe, but we also find that some customer pain points have not been well addressed, such as the problem of mode switching during real-time control of position and force, how to improve response speed while ensuring the accuracy of press force control, and the problem of real-time visual positioning and servo position response. We will continue to explore the industry pain points to provide better product and technical support services Domestic customers. "